A reliable source and stockist of incoloy 800h/800ht bars is Shasan Piping Solution. A group of experts who have begun compiling data and helped with the production, storage, and distribution of excellent alloys are responsible for maintaining our relationship. Our main goal is to provide our customers with cutting-edge necessities that satisfy their sweeping product needs. For all of your Incoloy 800H and 800HT bar needs, get in touch with us right now.

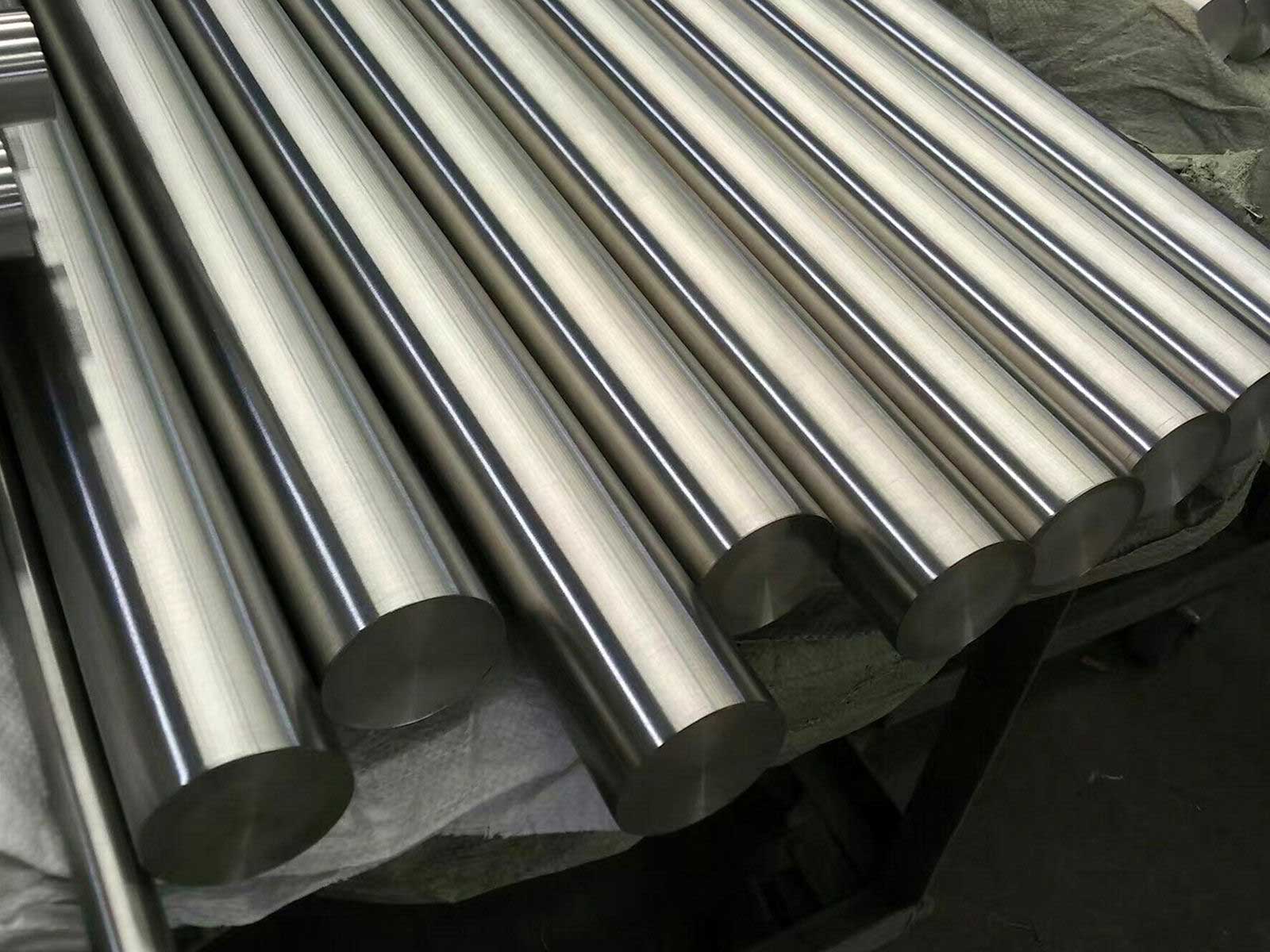

Significantly specialized materials called Incoloy 800H and 800HT are employed in a wide range of modern applications. The carbon concentration of their alloy composition is the primary distinction between Incoloy 800H and 800HT. Compared to Incoloy 800HT, which achieves stronger strength and better assurance from high-temperature conditions, Incoloy 800H has more carbon and looks different. Round bars made of Incoloy 800H/800HT exhibit crucial features that make them important for a variety of applications. These alloys of nickel, iron, and chromium are remarkably resistant to oxidation and disintegration at high temperatures. They can withstand high temperatures because of their great strength, amazing jerk resistance, and warm, unwavering quality. Additionally, they exhibit assurance against pressure disintegration breaking caused by chloride, nitridation, and carburization.

Our expertise lies in providing and supplying Incoloy 800H and 800HT bars to address the problems faced by businesses. Our extensive product line combines UNS N08811 and ASTM B408 bars, which are updated in compliance with the most important industrial requirements. We are aware that modern materials must be dependable and of high quality. To guarantee that our clients receive the highest quality, the combination of our materials is carefully tested and quality controlled in this way. Our bars undergo a battery of tests to verify their mechanical and authentic qualities, guaranteeing that they are appropriate for the intended use.

In spite of our superior goods and efficient delivery, we are quite proud of our outstanding customer support teams. Most of the time, we are available right away to brief our clients on how to use our ASTM B408 UNS N08810 bars as best we can. In addition, we guarantee unambiguous and straightforward methods of communication to inform and reenergize our customers regarding their orders.

| Standard | ASTM B408 / ASME SB408, AMS 5766 |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round bar size | Diameter: 3-~800mm |

| Hex Bar size | 2-100mm A/F |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square bar size | 4 to 100mm |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Rectangular Size | 33 x 30mm to 295 x 1066mm |

| Hex Bars Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Condition | Stainless & Stainless, annealed |

| Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Processing | Bar cutting to 650mm |

| Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

| Eastern Europe | Aisa | North America | Western Europe | Mid East/Africa |

| Australia | Central/South | UAE | America | Portugal |

| Spain | Indonesia | Italy | Angola | Poland |

| Brazil | Sri Lanka | Russia | China | Singapore |

| Oman | Venezuela | Costa Rica | USA | Qatar |

| Thailand | Canada | Saudi Arabia | Bahrain | Egypt |

| Malaysia | Turkey | Mexico | China | Peru |

| United States | Nigeria | Jordan | Kuwait | Dubai |

| Bangkok | Iran | Germany | UK | New Zealand |

| Vietnam | South Africa | Mexico | Kazakhstan |

| Mumbai | Ahmedabad | Bhopal | Bikaner | Pune |

| Delhi | Chennai | Visakhapatnam | Mangalore | Nagpur |

| Bangalore | Kolkata | Siliguri | Assam | Indore |

| Hyderabad | Surat | Nashik | Cochin | Thane |

| Faridabad | Rajkot | Aurangabad | Bhavnagar | Ranchi |

| Coimbatore | Mysore | Salem | Tirupur | Bikaner |

| Raipur | Bhubaneswar | Bhilai | Ankleshwar | Bhiwandi |

| Vadodra | Kochi |