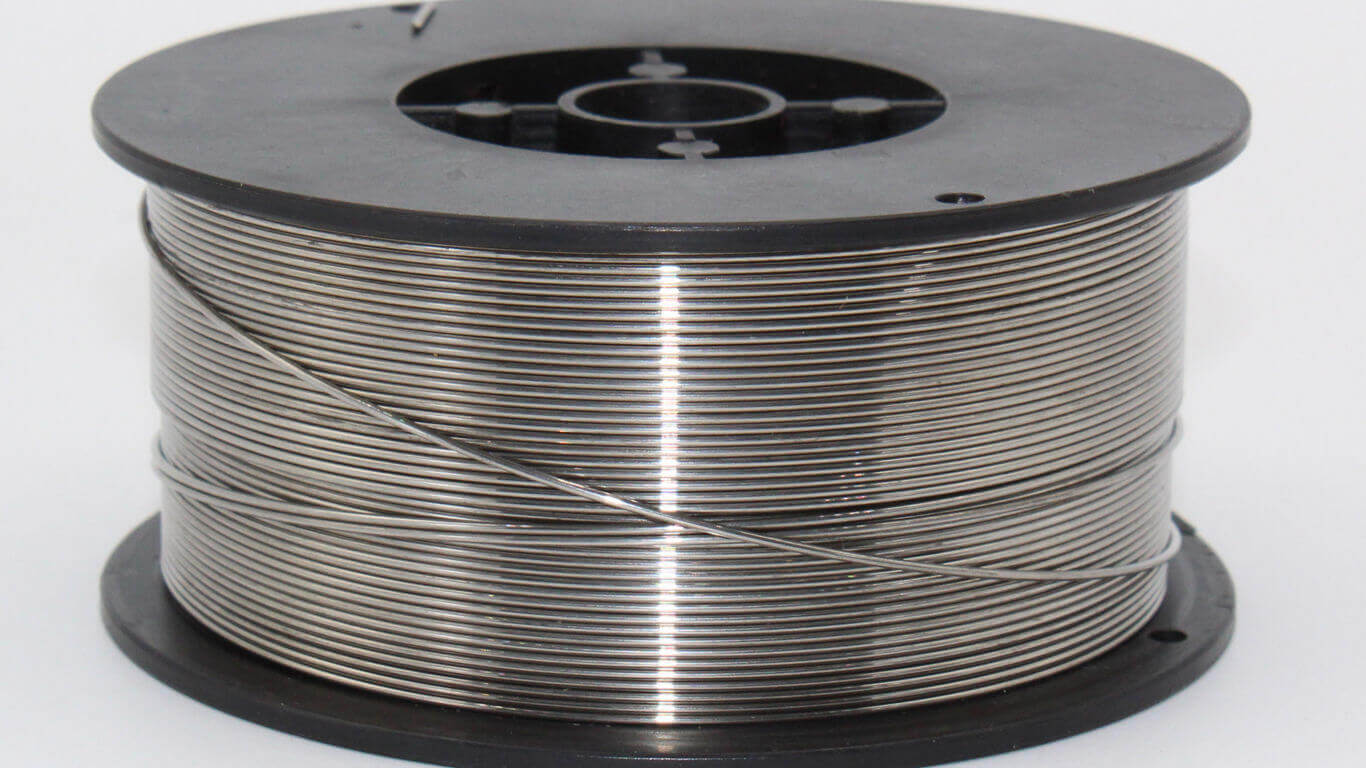

Shasan Piping Solution is a significant supplier and exporter of Nickel 200 Wires. We make them open in custom subtleties, plans, lengths, thickness, widths, and that is just a short glance at something greater. We are known exporter in the general market of ferrous and non ferrous things. Our clients can intrigue for nickel wires as exhibited by their application necessities.

Nickel 200 Wires are made with the help of the different compound affiliations like carbon, manganese, silicon, copper, sulfur, chromium, iron, nickel, nitrogen, and so on too. These nickel wires should give physical and mechanical properties like thickness, relaxing point, adaptability, yield strength, amazing inflexible nature, extending, warm conductivity, electrical conductivity, and modulus of augmentation. These wires are settled on with various choices like breadth, shape, size, length, width, thickness, types, structures, condition, surface, application, standard, finish, opposition, and so on moreover. These wires are available in many sorts, for instance, reshape wire, made never-endingly wire.

ASTM B160 Nickel 200 Wire, Nickel 200 Wires, Nickel N02200 Wires, Nickel Compound 2.4066 Wires, Nickel 200 Wires, 200 Nickel Wire, Nickel 200 Wires Manufacturers In Mumbai, India

Nickel 200 Wires are material in various organizations, for instance, offshore oil entering ventures, petrochemicals industry, power age plant, drug industry, substance gear, seawater equipment, drug equipment, specialty manufactured industry, paper industry, squash industry, heat exchanger, and condenser. These wires are furthermore significant in many general purposes like valves, shaft, shipbuilding, structure improvement, transportation equipment, length advancement, warmer parts, and various temperatures safe things.

Nickel 200 Wires are made with the best material and incredible mechanical and genuine properties. These wires are a respectable blend of formability, usefulness, welding, and resistance from the high temperatures. These wires are outrageous, hard, and made with the protected material to work at high temperatures. These wires are also protected structure the entire expansive disintegration like crevice utilization, stress breaking, pitting impediment, and impact disintegration. These wires are protected design the oxidizing, reducing and fair circumstances. These wires have the low electrical and warm conductivity that helps the wires with contradicting the electric.

Nickel 200 Wires need to go through many tests after the creation from the business, for instance, ejecting test, fixing test, enormous scope test, small test, hydrostatic test, ultrasonic test, pitting test, radiography test, hardness test, manufactured test, mechanical test, PMI test, and so on as well.

ASTM: ASTM B 160 / ASME SB 160

Dimensions: ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360

Size: 1mm -14mm

Diameter (mm): 0.60 - 6.00

Coil weight (kg): 80-300 kgs max

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

|

Nickel 200 |

2.4066 |

N02200 |

NW 2200 |

NA 11 |

НП-2 |

N-100M |

Ni 99.2 |

|

Grade |

C |

Mn |

Si |

S |

Cu |

Fe |

Ni |

|

Nickel 200 |

0.15 max |

0.35 max |

0.35 max |

0.01 max |

0.25 max |

0.40 max |

99.0 min |

|

Element |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

Nickel 200 |

8.9 g/cm3 |

1446 °C (2635 °F) |

Psi – 67000 , MPa – 462 |

Psi – 21500 , MPa – 148 |

45 % |

| Eastern Europe | Aisa | North America | Western Europe | Mid East/Africa |

| Australia | Central/South | UAE | America | Portugal |

| Spain | Indonesia | Italy | Angola | Poland |

| Brazil | Sri Lanka | Russia | China | Singapore |

| Oman | Venezuela | Costa Rica | USA | Qatar |

| Thailand | Canada | Saudi Arabia | Bahrain | Egypt |

| Malaysia | Turkey | Mexico | China | Peru |

| United States | Nigeria | Jordan | Kuwait | Dubai |

| Bangkok | Iran | Germany | UK | New Zealand |

| Vietnam | South Africa | Mexico | Kazakhstan |

| Mumbai | Ahmedabad | Bhopal | Bikaner | Pune |

| Delhi | Chennai | Visakhapatnam | Mangalore | Nagpur |

| Bangalore | Kolkata | Siliguri | Assam | Indore |

| Hyderabad | Surat | Nashik | Cochin | Thane |

| Faridabad | Rajkot | Aurangabad | Bhavnagar | Ranchi |

| Coimbatore | Mysore | Salem | Tirupur | Bikaner |

| Raipur | Bhubaneswar | Bhilai | Ankleshwar | Bhiwandi |

| Vadodra | Kochi |