Half Coupling is a connector which is used to screw two pieces of line together using hung Coupling. ASME B16.11 Hung Half Coupling are basically hung toward one side. The far edge is welded or in any case joined to the preparation. Stainless Steel Hung Half Coupling are fittings that assistance to make or end pipe runs. Hung Half Coupling collusion arranges two Lines and Cylinders toward each other.

Stainless Steel Hung Half Coupling Manufacturerss in India. We are stacking dealer of ASME B16.11 Hung Coupling, Delivered Screwed Half Coupling, Hastelloy C22 Made Coupling and Mix Steel Designed Screwed Half Coupling at gigantically silly effort contemplating reasonable master hours in India and entire wellspring of extraordinary ANSI B16.11 Created Hung Half Coupling, most exceptionally savvy game plan, cost open in Mumbai, India.

We are strong manufacuter of 3000LB Hung Half Coupling valued by Saudi Aramco. We have worked with store of Made Hung Half Coupling.Nutech Abroad is stockist of complete level of A182 Gr F347 NPT Hung Half Coupling, Stainless Steel Hung Half Coupling in various sizes. Call us to buy ASME B16.11 Screwed Coupling, most extremely brilliant plan, cost in India, demand latest worth outline of Delivered Screwed Half Coupling including A182 Hung Line Half Coupling, Screwed Half Coupling and Copper Nickel Hung Coupling.

We are strong Supplierss Created Hung Half Coupling to Kuwait, Canada, UK, Egypt, Sweden, France, Oman, Turkey, Thailand, Indonesia, Australia, Bahrain, Qatar, Germany, USA, UAE, Italy, Russia, Malaysia, Iran, Israel, Singapore, Sri Lanka and Saudi Arabia.

We are most basic Supplierss and exporter of SS 310 Hung Half Coupling, most extremely shrewd course of action, cost as we are maybe the most staggering Supplierss and master of Hung Half Coupling 3000 in Indium. We have our stocking wholesalers in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. In reality look right away our Hung Half Coupling 1/2 expense going before buying Hung Line Half Coupling from India or China. comparatively mail for our live reasonably of 2 Hung Half Coupling to check types and sizes with our organized stock we can give you best expense of 1 Hung Half Coupling.

We could besides anytime give free occasion of ASME B16.11 Half Coupling Threaded,Nutech Abroad is having our Seller and Dealer in Ghaziabad, Kolkata, Aurangabad, Khopoli, Pune, Tamil Nadu, Jaipur, Madhya Pradesh, Delhi, Punjab, Haryana, Ahmedabad, Bhosari, Karnataka, Nagpur, Faridabad, Karnataka, Rajasthan, Raipur, Ludhiana, Maharashtra, Uttar Pradesh, Chhattisgarh, Vadodara, West-Bengal,Bangalore, Chennai (Madras), Rajkot, Gujarat, Indore, Gurgaon, Kolhapur. So enduring you are looking for best expense of Half Coupling ASME B16.11 or 1/2 Hung Half Coupling, Nickel Composite 200 Half Coupling near you with most restricted time transport or free occasion of Inconel Delivered Screwed Half Coupling.

| Specifications | Forged Threaded Half Coupling |

|---|---|

| Dimension Specification | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Threaded Half Coupling Forged Fittings Thread | NPT, BSPT, BSPP |

| Threaded Half Coupling FittingsType | DN15-DN1200 |

| End | Threaded, Welding, JIC |

| Threaded Half Coupling Fittings Pressure Rating | Threaded end-2000lb/ 3000lb/ 6000lbs |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Size Range | 1/8" NB TO 4" NB |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Threaded Half Coupling Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for Threaded Half Coupling Fittings |

|

| Application |

|

| Carbon Steel | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Stainless Steel Threaded Half Coupling | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Alloy Steel | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass | 3602 / 2604 / H59 / H62 / etc. |

| Inconel | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 |

| Hastelloy | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| 254 Smo | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other material | Tin bronze, Alumunum bronze, Lead bronze |

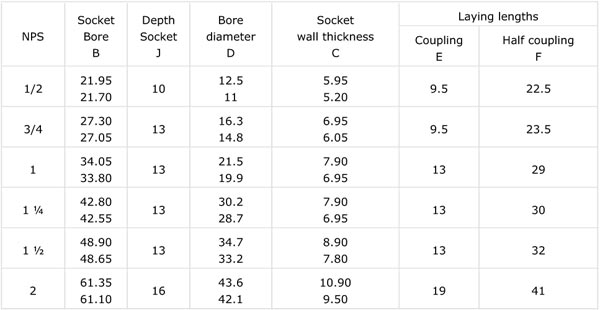

General notes:

Dimensions are in millimeters unless otherwise indicated.

Socket Bore (B) – Maximum and Minimum dimensions.

Bore Diameter (D) – Maximum and Minimum dimensions.

Socket wall thickness – (C) – Average of Socket wall thickness.

Dimensional tolerances laying lengths – (E & F)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2½ to NPS 4 = +/- 2.5 mm

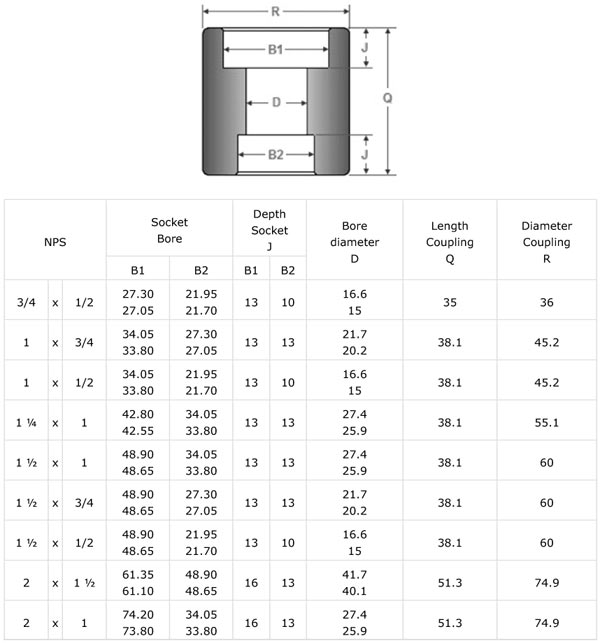

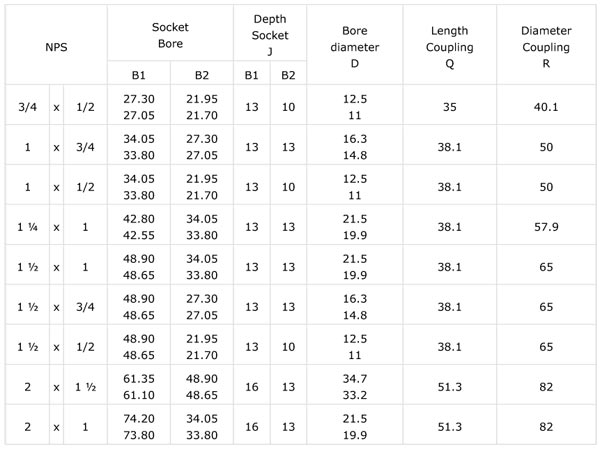

General notes:

Dimensions are in millimeters unless otherwise indicated.

Socket Bore (B1 / B2) – Maximum and Minimum dimensions.

Bore Diameter (D) – Maximum and Minimum dimensions.

| Eastern Europe | Aisa | North America | Western Europe | Mid East/Africa |

| Australia | Central/South | UAE | America | Portugal |

| Spain | Indonesia | Italy | Angola | Poland |

| Brazil | Sri Lanka | Russia | China | Singapore |

| Oman | Venezuela | Costa Rica | USA | Qatar |

| Thailand | Canada | Saudi Arabia | Bahrain | Egypt |

| Malaysia | Turkey | Mexico | China | Peru |

| United States | Nigeria | Jordan | Kuwait | Dubai |

| Bangkok | Iran | Germany | UK | New Zealand |

| Vietnam | South Africa | Mexico | Kazakhstan |

| Mumbai | Ahmedabad | Bhopal | Bikaner | Pune |

| Delhi | Chennai | Visakhapatnam | Mangalore | Nagpur |

| Bangalore | Kolkata | Siliguri | Assam | Indore |

| Hyderabad | Surat | Nashik | Cochin | Thane |

| Faridabad | Rajkot | Aurangabad | Bhavnagar | Ranchi |

| Coimbatore | Mysore | Salem | Tirupur | Bikaner |

| Raipur | Bhubaneswar | Bhilai | Ankleshwar | Bhiwandi |

| Vadodra | Kochi |